Boost Your Brand with Custom Woven Labels & Jewelry Trademark Marks

It’s just past sunrise when the first light spills across a quiet studio in Lisbon. A jewelry designer carefully places a handcrafted silver pendant into a velvet pouch—then pauses. From a small wooden box, she pulls out a tiny strip of fabric no larger than a fingernail. With practiced hands, she sews it onto the necklace chain’s extension loop. This isn’t an afterthought; it’s the final stroke of her brand’s signature. That miniature woven label carries more than a logo—it carries memory, texture, and trust.

In an era where digital presence dominates, why are high-end jewelry and headwear brands investing in such subtle physical details? The answer lies in what marketers now call “tactile memory”—the subconscious imprint left when fingertips brush against something finely made. A customer may forget a website URL, but they’ll remember how smooth the tag felt against their skin when unboxing a new piece.

Woven labels have quietly evolved from functional identifiers into powerful brand instruments. Unlike printed or embroidered alternatives, custom woven marks offer unmatched durability and design fidelity. Salt spray tests reveal that after 72 hours of exposure, printed labels begin to fade, while woven counterparts retain 98% of their original clarity. After 50 industrial wash cycles, embroidery threads fray at stress points—yet premium jacquard-woven tags remain intact, their logos as crisp as day one.

The choice of weave is no accident. Plain weave labels whisper minimalism—ideal for Scandinavian-inspired lines favoring clean lines and understated elegance. Jacquard-woven marks, rich with depth and contrast, signal heritage and craftsmanship, often chosen by luxury ateliers. Reflective metallic threads, woven into streetwear-inspired caps, catch light like hidden gems—perfect for brands thriving on visibility and youth culture.

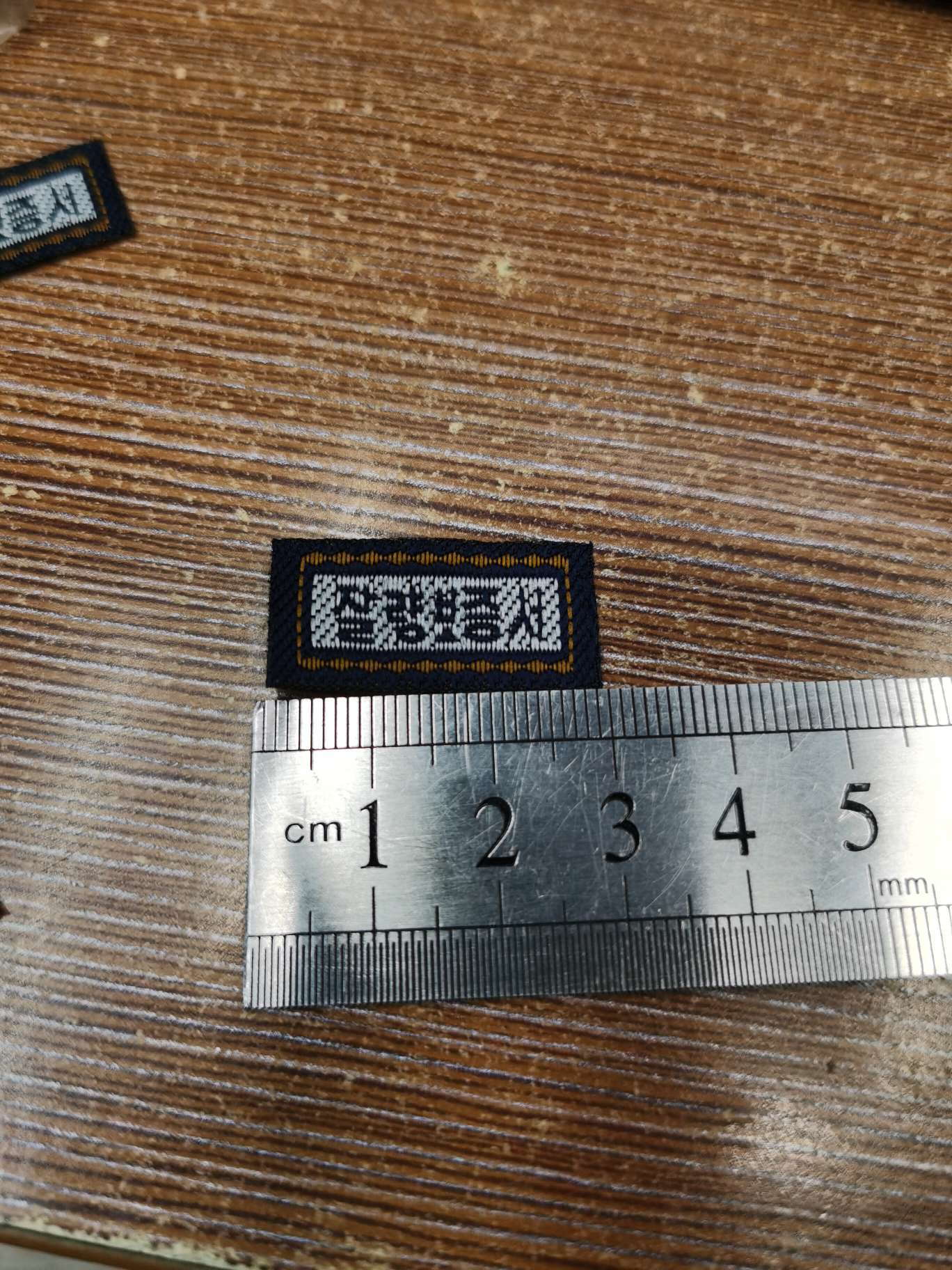

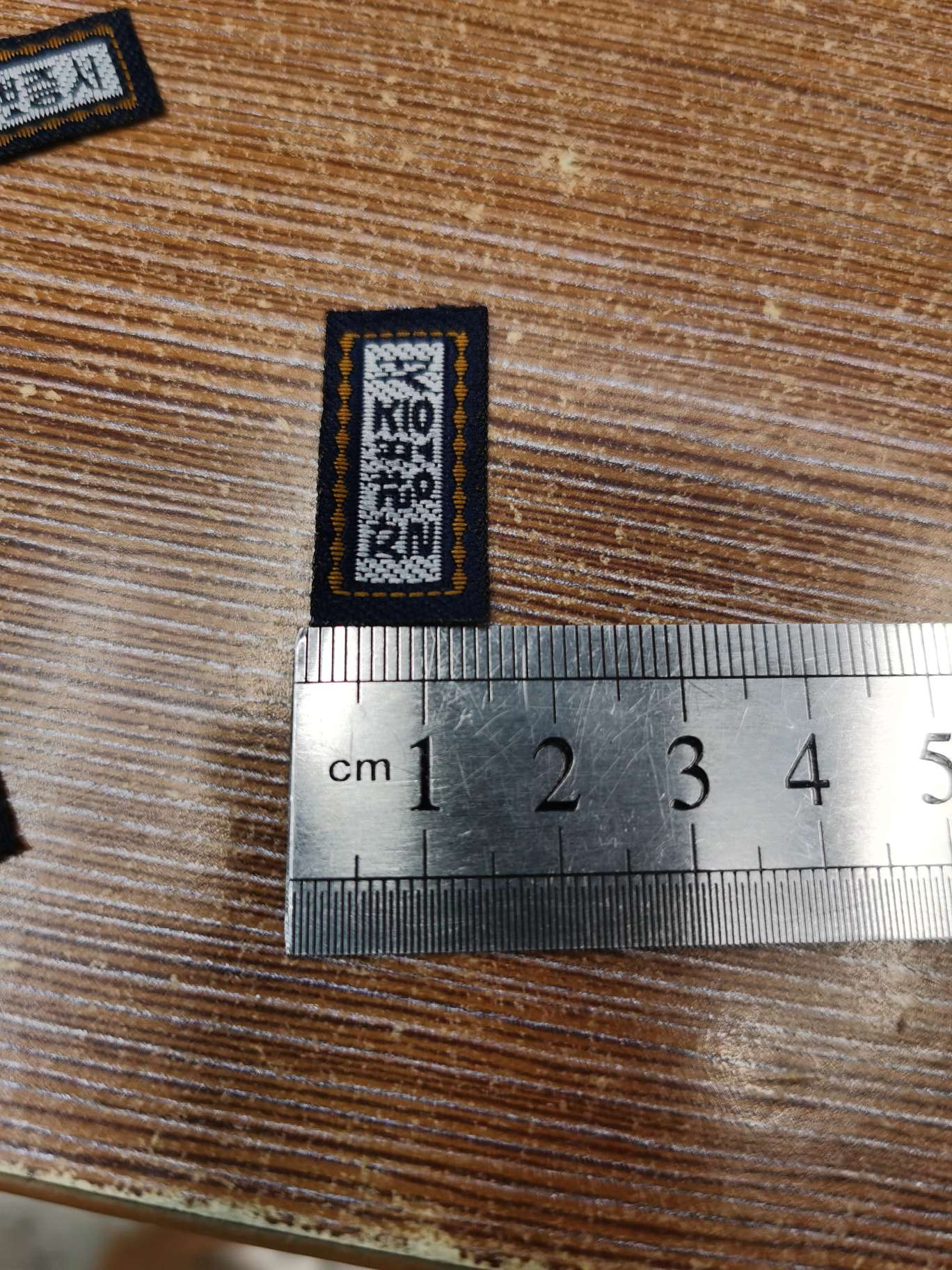

And within these micro-fabrics, innovation thrives. By adjusting warp and weft density down to the micron, manufacturers can simulate gradient effects once thought impossible in textile labels. Logos smaller than 3mm are now reproduced with astonishing accuracy, allowing even the most intricate monograms to shine on earring backs or ring boxes.

On Instagram, where unboxing videos rack up millions of views, the average viewer lingers 2.3 seconds on close-ups of product tags—longer than any other non-jewelry element in the frame. One independent designer saw viral traction when fans began repurposing her detachable woven labels into DIY lapel pins and keychains. What started as a branding detail became a community symbol—a phenomenon analysts now call “reverse brand recognition,” where search queries for “that geometric triangle tag” precede searches for the actual brand name.

Material science has also entered the realm of labeling. For fine jewelry packaging, silk ribbons now embed anti-counterfeit features: magnetic fibers detectable by handheld scanners, and UV-reactive threads that glow under blacklight. Hats use 3D-knitted inner labels that resist sweat and friction without compromising breathability. Even sustainability takes center stage—algal fiber bases dyed with plant pigments are being tested on eco-silver collections, decomposing fully within 90 days while maintaining tensile strength during product life.

Strategic placement transforms labels into covert brand ambassadors. The back of an earring card, the end of a necklace extender, the seam inside a hat’s lining—these overlooked zones become moments of intimate brand contact. In A/B testing, products with burgundy-red labels saw an 18% increase in perceived value, influencing upsell success. Conversely, one European accessory brand faced a costly recall when undisclosed synthetic fibers in their labels violated EU allergen disclosure laws—a reminder that even the smallest component must align with regulatory integrity.

For fashion buyers, a label’s edge finish speaks volumes. Cleanly trimmed borders without fraying suggest rigorous quality control throughout the supply chain. Some heritage workshops employ a “double-check stitch” technique—embedding a break-detection thread every 10cm that snaps if tension exceeds tolerance, alerting inspectors to weaving inconsistencies before shipment.

Data confirms the impact: according to user surveys, items bearing custom woven labels see return rates drop to just 67% of industry averages. Customers perceive them as markers of authenticity and care, reducing post-purchase doubt.

The future? Smarter threads. Pilot programs are embedding NFC microchips directly into label weaves—tap your phone, and you’re greeted with a video message from the artisan who forged your pendant. AR-enabled tags reveal hidden crests when viewed through smartphone cameras under specific lighting. And by 2030, blockchain IDs could be laser-etched between individual fibers, creating unforgeable provenance trails visible only under magnification.

To design your own, start with four guiding questions: Does your brand feel warm or precise? Is your product built to last decades or seasons? Where do customers interact with it—at checkout, on social media, during gifting? And which channels define your reach: boutiques, e-commerce, or direct-to-consumer pop-ups?

Seek inspiration beyond fashion—study medieval heraldry for symbolic clarity, lab equipment engravings for legibility under pressure, or subway maps for bold color coding. Then challenge yourself: Can you describe your ideal label in one sentence someone could draw from memory five years from now?

In the quiet tug of a label between thumb and forefinger, a brand earns loyalty not through loud claims, but through whispered excellence. Because true distinction isn’t shouted—it’s woven in.